- Applications

- Logistics solution

Supermarket distribution center

- Inbound and Outbound

- Transfer system

- Sorter

TC(cross dock) and DC(storage) functions are combined.

The ultra-high speed sorter helps the client sort to its stores.

Overview

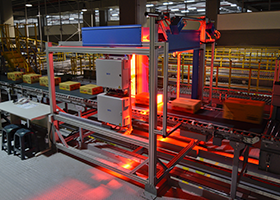

A distribution center for daily commodities. The customer operated cross dock operation and DC operation separately before Okura implemented the integrated system coping with both operations using a ultra high capacity shoe sorter, UNISORTER FSⅣ equipped with 68 chutes to maxmize his logistics to stores.

System benefits

- Simultaneous handling of cross dock items and DC ones has enhanced productivity by means of UNISORTER FSⅣ, which leads to shorter delivery lead time to stores. This has also reduced the loss of sales opportunities.

-

106m long UNISORTER FSⅣ with double-sided 68 chutes

-

5Inbound consisting of 5 conveyor lines

-

Barcode scanner reading 4 sides of boxes

-

Outbound line

-

DC items handling area

VoiceFeedback from customer

The previous system was not so efficient because TC and DC were operated separately. The newly installed high capacity shoe sorter has improved the efficiency of operations, in addition to accurate shipping results.

- Applications Navigation

-

- Processed food plant

- Rice-milling plant

- Brewery plant

- Food plant

- Beverage factory

- Snacks factory

- Vegetable factory

- Paper milling factory

- Pharmaceuticals distribution center

- Media items distribution center

- Books distribution center

- Daily commodities center

- Refrigerated food center

- International express cargo logistics center

- Apparel goods distribution center

- Supermarket distribution center

- E-commerce distribution center

- Sports goods distribution center

- Airport baggage handling system

- Agricultural products handling center