Picking equipment

Pickatoru seriesLight-to-pick systems

Easy, accurate, and fast picking, using light-based instructions.

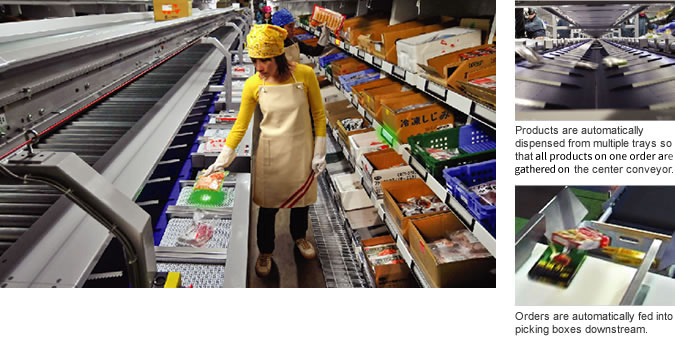

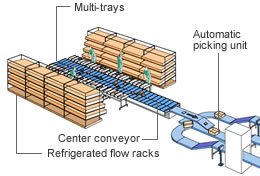

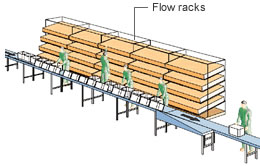

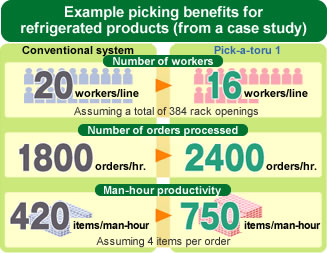

Pickatoru 1 (Multi-tray type)

Pick one item when the indicator lights up.

Then, the multi-tray and center conveyor do the rest of the operation automatically.

In these systems, products taken from flow racks are placed in multiple trays. After one item is placed on its relevant tray the light on the tray goes out and the item is dispensed automatically onto the center conveyor. The other items on the same order are collected on the center conveyor running downstream. This approach is ideal for refrigerated and other products with consistent shape and other properties.

- The flow rack LED indicator turns on, and the multi-tray LED indicator turns on.

- A worker picks one item from the opening with the illuminated LED indicator.

- The worker places the product in the multi-tray with the illuminated LED indicator.

- The product is automatically dispensed from the multi-tray.

- All items on the order are assembled on the center conveyor and automatically fed into a picking box.

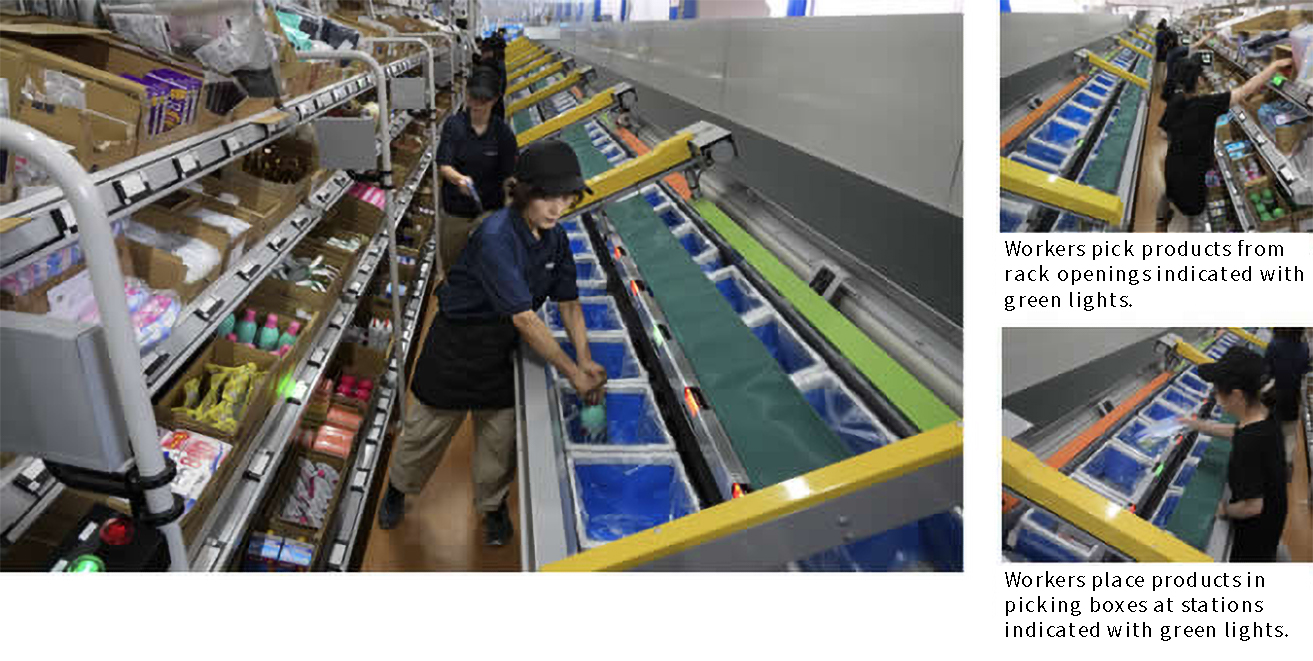

Pickatoru 2 (Picking box manual fill type (general-purpose type))

There is no need for operatiors to want to arrive with this two-lane system, which facilitates high-productivity and continuous picking.

In these systems, products taken from flow racks are placed manually in picking boxes such as collapsible containers and shipping cartons. Since there are two lanes of picking box stations, there is always a picking box available front of the workers. Since products are manually placed, this approach is ideal for use with refrigerated goods, dry goods, and agricultural produce that include items fragile or difficult to grab with hands.

- The LED indicator on the flow rack turns on, and the LED indicator on the corresponding picking box station turns on.

- A worker picks a single item from the opening illuminated by the LED indicator. *

*If multiple items, the quantity will be shown on the quantity indicator. - The worker places the product(s) in the picking box with the illuminated LED indicator.

- If other items remain to be picked, the worker repeats Steps 1 through 3.

- Once picking for all zones is complete, the picking box is sent on.

Pick-a-toru 3 (Picking box manually filled type (general-purpose type))

This one-lane system is ideal for low-volume picking applications.

In these systems, products taken from flow racks are placed manually in picking boxes such as collapsible containers and shipping cartons. Since products are manually placed, this approach is ideal for use with refrigerated goods, dry goods, and agricultural produce that include items fragile or difficult to grab with hands.

- The flow rack LED indicator turns on, and the LED indicator on the corresponding picking box station turns on.

- A worker picks a single item from the opening illuminated by the LED indicator. *

*If multiple items, the quantity will be shown on the quantity indicator. - The worker places the product(s) in the picking box illuminated by the LED indicator.

- If other items remain to be picked, the worker repeats Steps 1 through 3.

- Once picking for all zones is complete, the picking box is sent on.

Features

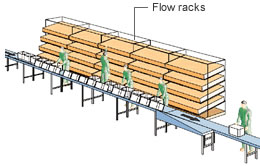

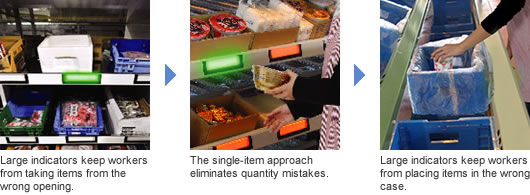

- Error-free picking

Large LED indicators instruct workers from which opening to pick an item and into which location to place it. Workers need only pick one item at a time in accordance to the light-based signs.

- Stress-free picking

Thanks to a simple and single-item picking approach that eliminates time to wait, anybody can perform picking work.

- Fast picking

These systems deliver high productivity without time to wait by eliminating time to be spent counting products and pressing "Done" buttons as in a case with conventional picking systems.

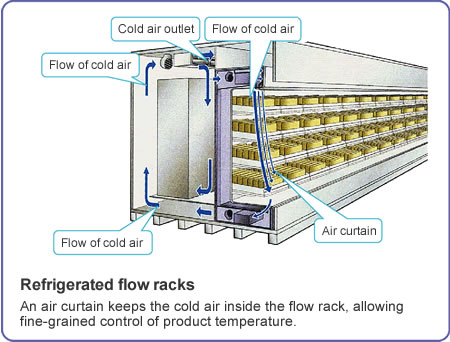

- Fine-grained product temperature control

In addition to normal-temperature flow racks, Okura has developed a refrigerated flow rack for the Pick-a-toru series that takes advantage of the latest temperature management technology to maintain the optimal temperature environment for products and workers alike.

- Picking equipment Navigation