Jabcon Series® Functions/Applications

Functions

① Standard high-quality, multifunctional belt

Jabcon models use multifunctional belts that are ideal for transporting food products, allowing a single system to accommodate a variety of products and transport conditions.

Whereas the typical belt that comes standard with a conveyor system only offers three functions, for example compatibility with food products and low-noise operation, the Jabcon II's multifunctional belt delivers ninefold functionality.

*For more information, please see the belt specifications, as a certain functions are not available with some models.

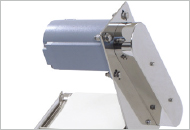

② Waterproof motor and control box

Thanks to its IP65 waterproof motor, the entire conveyor can be washed. The control box also features increased waterproofness with IP55 protection.

- IP65 waterproof motor (standard)

-

- IP55 waterproof control box (standard)

-

- RoHS-compliant waterproof control box

-

③ Easy belt removal

Models come standard with a mechanism for loosening the belt, allowing both surfaces of the belt to be cleaned quickly.

④ Stainless steel frame with HACCP design

The frame is designed for use in an HACCP environment. For example, there is no unnecessary gauging holes on the sides so that dirt cannot collect there.

There are no protruding parts on the inside of the frame (left), there is no unnecessary gauging holes on the sides.

⑤ More robust safety features

Jabcon models feature a safe design that is engineered to keep objects from becoming caught in rotating pulleys or the belt tracking area.

Rotating end pulleys fit inside the width of the belt.

Return wheels (which are removable) prevent belt sag.

⑥ Embossed finish for energy savings

The carrier plate on which the belt rests features an embossed finish to reduce transport resistance. This design yields energy savings.

Transport resistance during conveyor operation has been reduced thanks to a reassessment of the shape of embossed areas on the carrier plate (oval slots) and their pitch.

Combine components to suit your application

Select from a variety of drive unit positions, legs, and guides to suit your application.

- Drive unit positions

-

Side-mounted motor

Underneath

Above

Applications

- Bento plant

-

A six-meter-long JTH model being used on a food placement line.

- Crab processing plant

-

After packing, crab is sent to a freezer by the lower-level JMF conveyor.

- Bread plant

-

A JBG model with a work table on both sides

- Fish paste plant

-

Tubes of fish paste, which are prone to roll around, are reliably transported by a JHV model.

- Prepared food plant

-

A JFE model being used on an inarizushi production line.