Belcon Mini Functions/Applications

Functions

① More robust environmental features

Belcon Mini delivers more robust energy-saving and environmental features by using a high-efficiency motor and RoHS-compliant parts.

- High-efficiency brushless motor

-

Belcon Mini uses a brushless motor with 25% lower power consumption than gearbox-equipped models (according to an Okura comparison).

- RoHS-compliant parts

-

All parts comply with the RoHS Directive for greater environmental friendliness.

- Large-diameter stainless steel pulleys

-

Belcon Mini uses large-diameter snub and takeup pulleys to lower the belt's bending resistance and save energy.

② Standard high-quality, multifunctional belt

Belcon Mini uses multifunctional belts that are ideal for transporting small objects, allowing a single system to accommodate a variety of products and transport conditions.

Whereas the typical belt that comes standard with a conveyor system only offers three functions, for example compatibility with food products and low-noise operation, the Belcon Mini III's multifunctional belt delivers eightfold functionality.

③ Simple maintenance

We gave shape to feedback indicating customers want simpler maintenance.

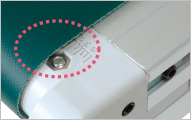

- Transparent cover for drive mechanism

-

A transparent cover lets you check for chain looseness and belt tension at a glance. There is no need to remove the cover when lubricating the drive mechanism, ensuring safety while keeping maintenance simple.

- Check belt tension at a glance

-

Graduations engraved on the transparent cover let you check belt tension at a glance.

- Easier adjustment of belt tracking

-

Graduated conveyor frames help you check the belt tracking position at a glance.

- Transparent cover for drive mechanism

-

Tracking adjustment can be performed from beside the end of the belt.

- Easy removal of end pulleys

-

Even when conveyors are placed in series (end to end), the end pulley can be removed upward.

④ More robust safety features

Belcon Mini features a safe design that is engineered to keep objects from becoming caught in rotating pulleys or the belt tracking area.

- More robust safety features at the end of and underneath the conveyor

-

Rotating pulleys fit inside the width of the belt.

The new design is engineered to keep objects from becoming caught from underneath the conveyor.

⑤ Double-grooved frame for easy mounting

In addition to allowing attachment of a variety of parts, the double-grooved design can accommodate M6 nuts (Type 1) anywhere on the side.

M6 nuts can be inserted anywhere on the side of the frame.

A variety of attachments such as guides and photoelectric switches can be mounted.

⑥ New slim-type models

The Belcon Mini series now includes new slim-type models whose drive units sit flush underneath the conveyor with no protruding parts. The design is extremely useful when mounting the conveyor on another device or machine.

Applications

- Prepared food plant

-

A spiral conveyor more than 200 m long made up of Belcon Mini units

- Somen noodle plant

-

A Belcon Mini conveyor installed after a metal testing process

- Crab processing plant

-

A DMH unit being used to transport products between processes using various machinery and devices such as packaging equipment and a metal detection system

- Dried rice seasoning plant

-

Products discharged from a filling machine are transferred to a packaging room by DMH conveyors.

- Vegetable sorting area

-

DMG conveyors being used to transport vegetables wrapped in plastic film to workers for packing